Unident

Unident Imported Vacuum Former

Unident Imported Vacuum Former

Couldn't load pickup availability

Features

Features

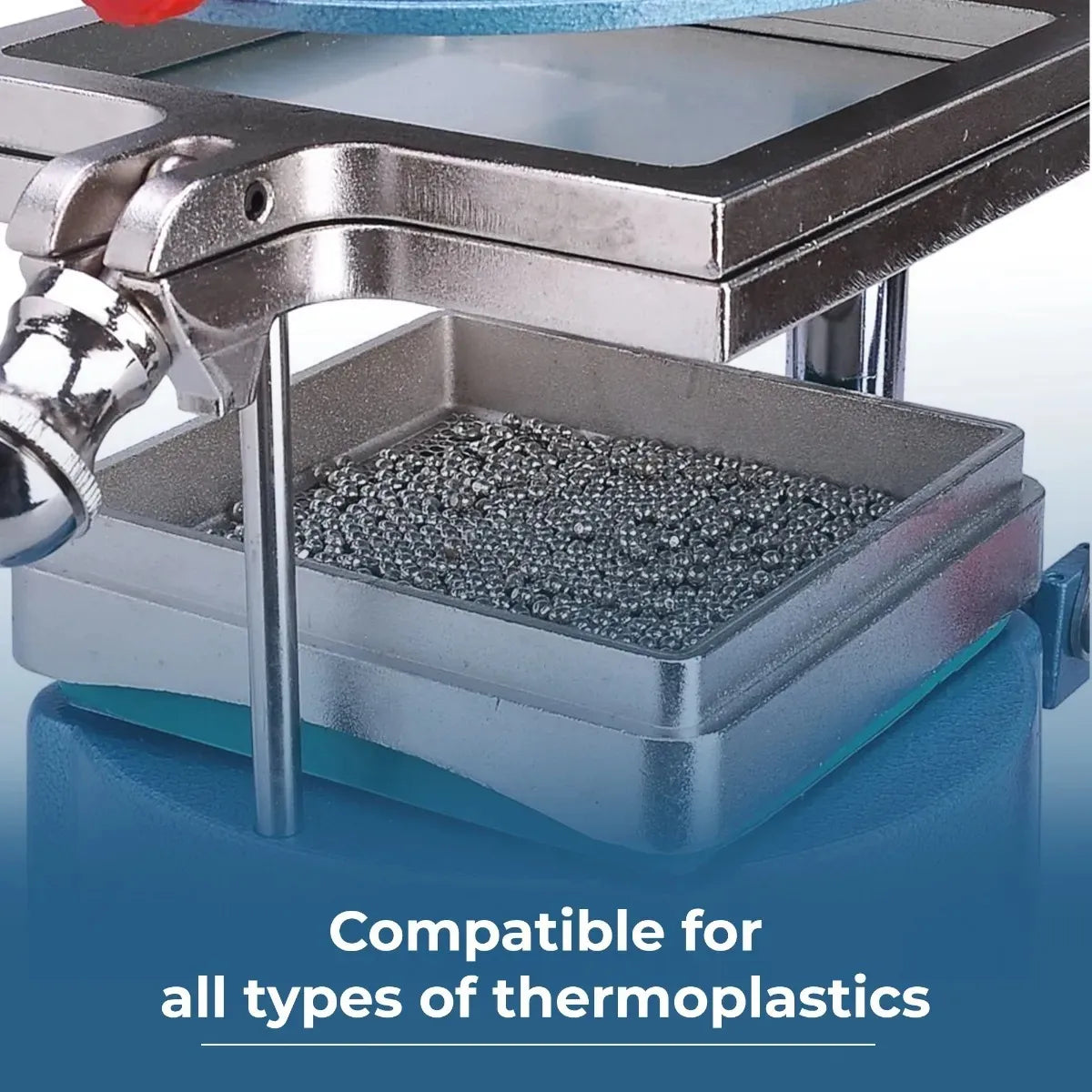

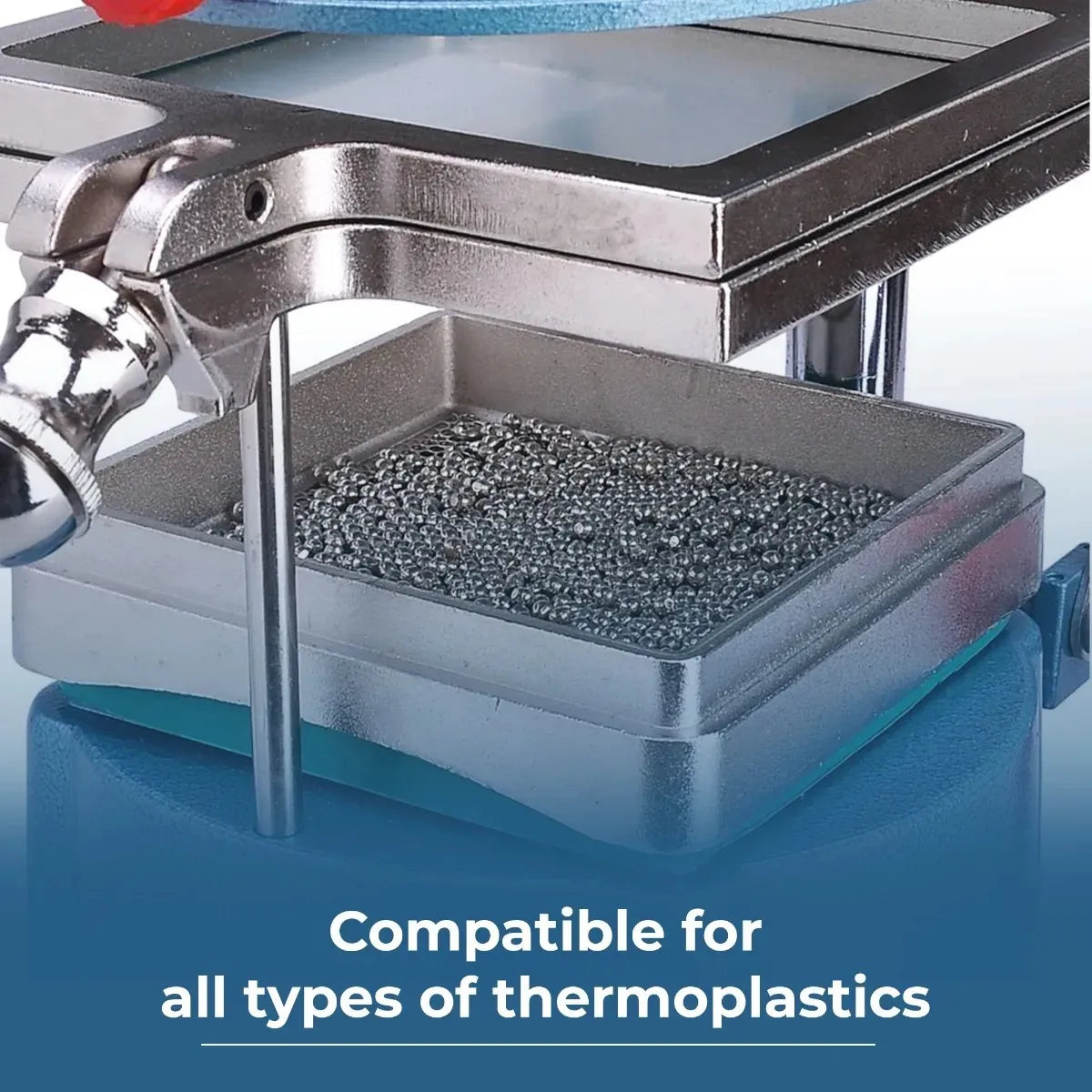

- Versatile Thermoforming: Enables precise thermoforming of thermoplastic sheets for a variety of dental appliances such as splints and trays.

- User-Friendly Design: Designed with ease of use in mind, making it suitable for dental professionals at various skill levels.

- Efficient Heating Element: Features a powerful heating element that quickly softens thermoplastic sheets for optimal forming.

- Consistent Results: Provides consistent and reliable results, ensuring accurate adaptation of the thermoplastic material to dental models.

- Compact Construction: Compact and space-efficient design, making it suitable for dental laboratories with limited space.

- Durable Build: Constructed with durability in mind, ensuring a long service life with regular use.

- Precise Vacuum Forming: Offers a precise vacuum forming process for creating detailed and accurate dental appliances.

- Adjustable Settings: Allows for adjustment of heating times and temperatures to accommodate different thermoplastic materials and applications.

- Cooling Assistance: Equipped with features to aid in the cooling process, ensuring the formed material sets properly.

- Secure Material Placement: Provides a secure and even placement for thermoplastic sheets over dental models, preventing shifting during the forming process.

- Trimming Accessibility: Facilitates easy trimming of excess material, allowing for precise finishing of the formed dental appliances.

- Suitable for Various Applications: Versatility in creating a range of dental appliances, meeting the diverse needs of dental practitioners.

- Versatile Thermoforming: Enables precise thermoforming of thermoplastic sheets for a variety of dental appliances such as splints and trays.

- User-Friendly Design: Designed with ease of use in mind, making it suitable for dental professionals at various skill levels.

- Efficient Heating Element: Features a powerful heating element that quickly softens thermoplastic sheets for optimal forming.

- Consistent Results: Provides consistent and reliable results, ensuring accurate adaptation of the thermoplastic material to dental models.

- Compact Construction: Compact and space-efficient design, making it suitable for dental laboratories with limited space.

- Durable Build: Constructed with durability in mind, ensuring a long service life with regular use.

- Precise Vacuum Forming: Offers a precise vacuum forming process for creating detailed and accurate dental appliances.

- Adjustable Settings: Allows for adjustment of heating times and temperatures to accommodate different thermoplastic materials and applications.

- Cooling Assistance: Equipped with features to aid in the cooling process, ensuring the formed material sets properly.

- Secure Material Placement: Provides a secure and even placement for thermoplastic sheets over dental models, preventing shifting during the forming process.

- Trimming Accessibility: Facilitates easy trimming of excess material, allowing for precise finishing of the formed dental appliances.

- Suitable for Various Applications: Versatility in creating a range of dental appliances, meeting the diverse needs of dental practitioners.

Description

Description

The Unident Imported Vacuum Former is a high-performance dental device designed for precise fabrication of thermoformed appliances. It effectively heats and molds thermoplastic sheets over dental models, enabling the creation of custom-fit trays, splints, retainers, mouthguards, and surgical templates. Its compact and durable build ensures long-term reliability in dental clinics and laboratories. The machine delivers consistent suction and uniform heating, ensuring detailed adaptation for each application. Suitable for orthodontic, prosthodontic, and preventive procedures, it supports a wide range of tasks including bleaching trays, fluoride carriers, and implant guides. Its user-friendly operation enhances workflow, making it a must-have for efficient and accurate appliance fabrication.

Range of applications:

- Orthodontic retailers, dental arch splints.

- Periodontal disease and fluoride curing tray

- Temporary or permanent base plates, jaw holders, mouth guards

- Implant dental positioning plates, retainers

Specification

Specification

TECHNICAL SPECIFICATION:

- Material: Metal

- Power: 1000W

- Dimensions: 25 X 21 X 30cm

- Voltage: AC 220V 50HZ

- Weight: 6kg

Packaging

Packaging

- 1 x Vacuum Former Machine

- 1 x Manual

Direction to use

Direction to use

- Setup: Place the Unident Imported Vacuum Former on a stable and level surface in your dental laboratory.

- Power On: Connect the machine to a power source and turn it on. Allow it to reach the desired operating temperature.

- Select Thermoplastic Material: Choose the appropriate thermoplastic sheet based on the type of dental appliance you intend to create. Ensure the sheet is trimmed to the required size.

- Secure the Material: Place the trimmed thermoplastic sheet over the model or mold you wish to use. Ensure it is evenly distributed and properly secured.

- Heating Process: Position the model with the thermoplastic sheet into the heating area of the machine. Activate the heating element to soften the thermoplastic material. Follow recommended heating times and temperatures.

- Vacuum Forming: Once the thermoplastic material is adequately heated and pliable, move the model to the vacuum forming area. Activate the vacuum function to mold the softened material over the model.

- Cooling: Allow the formed material to cool and solidify. This can be expedited using a cooling fan or other cooling methods.

- Remove the Formed Appliance: Carefully remove the vacuum-formed dental appliance from the model. Ensure that the material has completely set and hardened.

- Trimming and Finishing: Trim any excess material from the formed appliance and perform any necessary finishing touches to achieve the desired shape and contours.

- Clean and Maintain: Clean the machine and remove any residual material. Follow the manufacturer's guidelines for maintenance to ensure the longevity of the Unident Imported Vacuum Former.

- Power Off: Turn off the machine and disconnect it from the power source.

Additional info

Additional info

Warranty

Warranty

Product Related Questions

Product Related Questions

Question Can we use square sheet ?

Answer: Yes, you can use a square sheet with the Unident Imported Vacuum Former.

Question What is the primary function of the Unident Imported Vacuum Former?

Answer: The machine is designed for thermoforming thermoplastic sheets to create dental appliances such as splints and trays.

Share