adin

Adin Twist Drills

Adin Twist Drills

Couldn't load pickup availability

The Adin Twist Drills are precision-engineered, two-step drills designed for dental implant procedures, ensuring optimal preparation of the implant site. These drills are meticulously crafted to enhance the efficiency and accuracy of the drilling process, contributing to successful implant outcomes. The two-step design allows for progressive enlargement of the osteotomy, minimizing trauma to the surrounding bone and ensuring a stable foundation for the implant. Adin Twist Drills are compatible with various implant systems, offering versatility in clinical applications. The unique geometry of the drill flutes ensures efficient cutting and removal of bone debris, reducing heat generation and the risk of bone necrosis. The drills are color-coded and laser-marked for easy identification and depth control, facilitating precise and safe drilling.

Features

Features

- Two-Step Design: Allows for progressive enlargement of the osteotomy, minimizing trauma and ensuring a stable foundation

- Precision Engineering: Enhances efficiency and accuracy in preparing the implant site

- Compatibility: Suitable for various implant systems, offering versatility in clinical applications

- Efficient Cutting: Unique geometry of the drill flutes ensures effective cutting and removal of bone debris

- Reduced Heat Generation: Designed to minimize heat generation, lowering the risk of bone necrosis

- Color-Coded: Color-coded for easy identification and quick selection during procedures

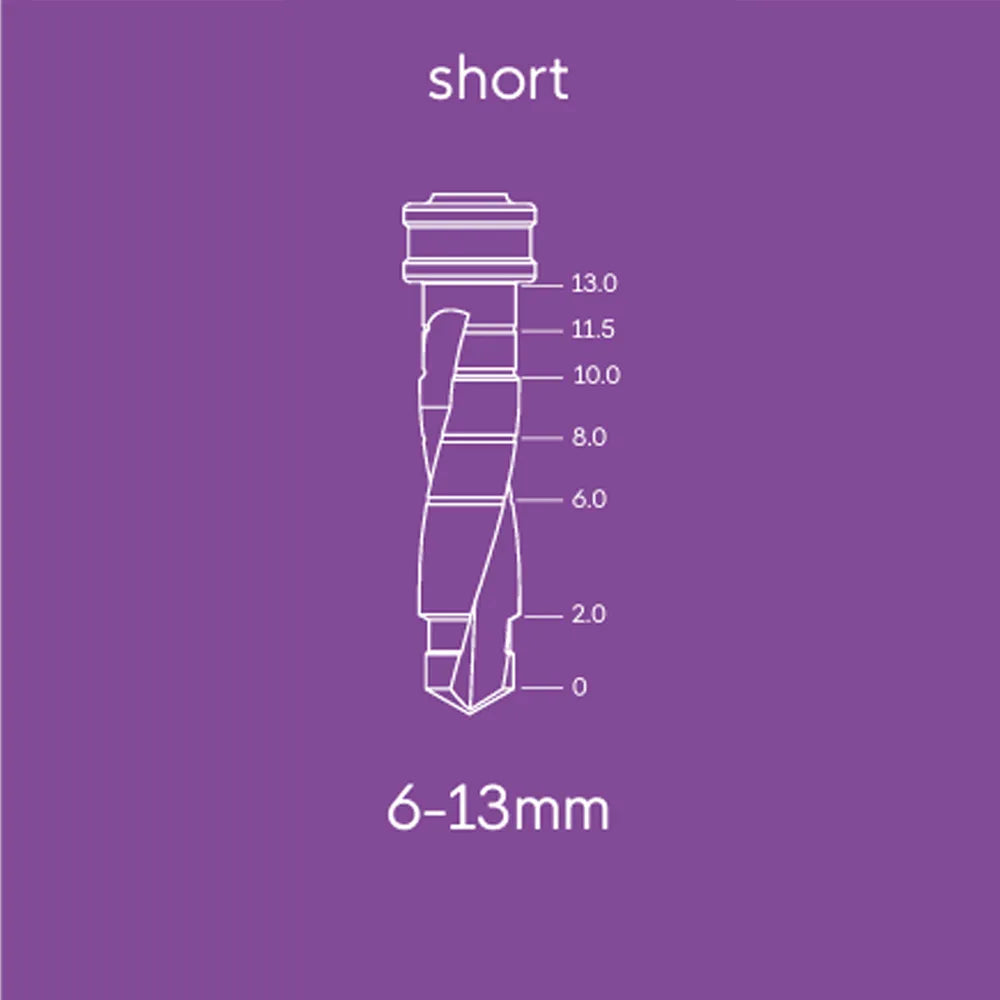

- Laser-Marked Depth Indicators: Ensures precise depth control, enhancing safety and accuracy

- Durability: Made from high-quality materials for long-lasting performance and reliability

- Smooth Operation: Designed to operate smoothly, reducing hand fatigue during prolonged use

- Sterilizable: Fully sterilizable to maintain hygiene and prevent cross-contamination

Description

Description

Specification

Specification

- Type: Two-step twist drills

- Material: High speed stainless steel

Packaging

Packaging

- 1 x Twist drill

Direction to use

Direction to use

Preoperative Planning:

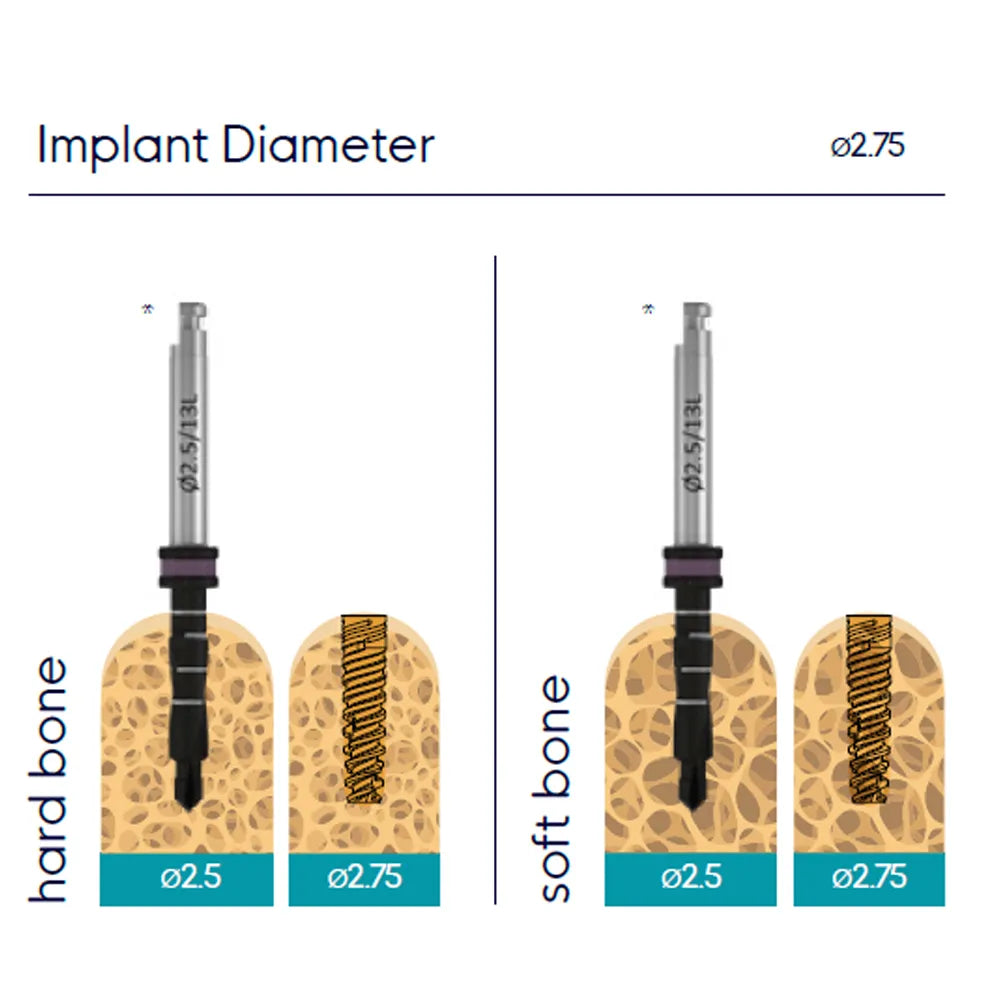

- Assess the implant site through clinical and radiographic evaluation. Select the appropriate size of the twist drill based on the implant diameter and length

Initial Drill Placement:

- Ensure the patient is appropriately anesthetized

- Begin with the pilot drill to create a guide hole at the planned implant site. Maintain steady and gentle pressure

First Step Drilling:

- Use the initial size twist drill to begin the osteotomy

- Insert the drill into the pilot hole, keeping it perpendicular to the bone surface

- Use irrigation to cool the drill and bone, reducing heat generation

- Drill at a controlled speed, applying moderate pressure. Withdraw the drill periodically to remove bone debris and ensure proper cooling

Second Step Drilling:

- Switch to the next size twist drill to enlarge the osteotomy

- Follow the same drilling technique, ensuring continuous irrigation and controlled speed

- Repeat the process until the osteotomy reaches the desired diameter and depth for the implant

Depth Control:

- Use laser-marked depth indicators on the drills to ensure precise depth control

- Verify the final osteotomy depth with a depth gauge if needed

Post-Drilling Care:

- After completing the osteotomy, irrigate the site to remove any remaining bone debris

- Inspect the osteotomy for proper size and depth, ensuring it matches the implant dimensions

Implant Placement:

- Proceed with implant placement following the standard protocol, ensuring the implant fits securely in the prepared osteotomy

Sterilization:

- After use, clean and sterilize the twist drills according to the manufacturer's guidelines to maintain hygiene and readiness for future procedures

Additional info

Additional info

- Country of Origin: Israel

- Manufacturer: Adin

Warranty

Warranty

- Warranty is not applicable for this product

Product Related Questions

Product Related Questions

Question : What are Adin Twist Drills used for?

Answer: Adin Twist Drills are used for precise and efficient osteotomy preparation in dental implant procedures.

Question : What materials are Adin Twist Drills made from?

Answer: Adin Twist Drills are made from high-quality stainless steel materials that ensure durability and effective cutting performance.

Question : How should Adin Twist Drills be maintained?

Answer: Adin Twist Drills should be cleaned and sterilized according to standard dental instrument protocols to ensure longevity and patient safety.

Question : What is the advantage of the two-step design?

Answer: The two-step design allows for incremental drilling, reducing heat generation and improving cutting precision.

Share