labodent

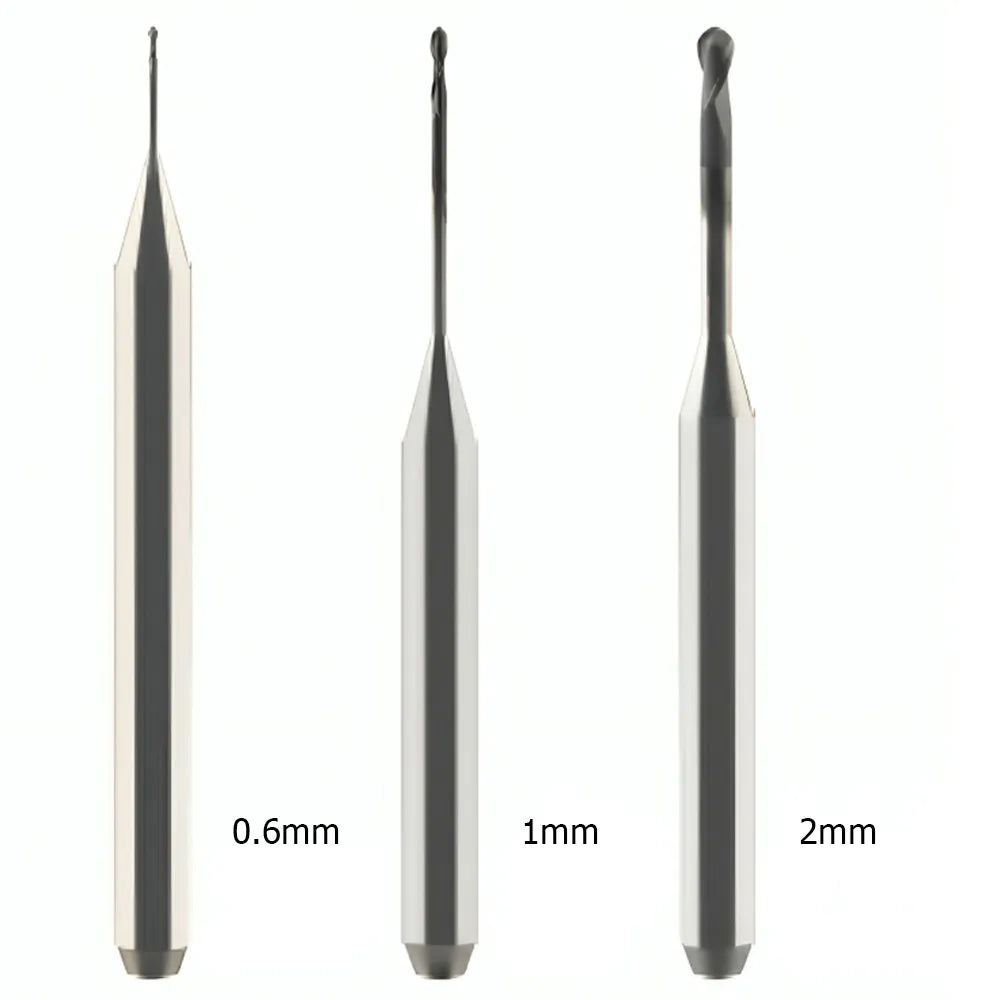

Labodent Milling Burs DC (Roland Type)

Labodent Milling Burs DC (Roland Type)

Couldn't load pickup availability

Labodent Milling Burs DC (Roland Type)

Labodent Precision introduces a game-changer in dental milling with their high-performance milling burs. Engineered for excellence, these burs offer an exceptionally sharp edge, reducing the risk of chipping or cracks in teeth during the milling process. Tailored for compatibility with Zirconia, these tools ensure precision in crafting dental restorations. The burs boast high tenacity, minimizing the risk of cracking, and a prolonged lifespan, ensuring longevity and cost-effectiveness. With superior hardness and coating adhesion, Labodent's milling burs guarantee consistent, high-quality results. Whether you're using an CAD/CAM milling machine or seeking an alternative with DLC technology, these burs provide the cutting-edge solutions needed for intricate dental work. Elevate your dental craftsmanship with Labodent Precision – where sharpness, durability, and precision converge for unparalleled results.

Features

Features

- Precision Sharpness: Experience unparalleled precision with an exceptionally sharp cutting edge, minimizing the risk of chipping or cracks in dental restorations.

- Zirconia Compatibility: Tailored for Zirconia, these burs ensure seamless integration with popular dental materials, providing optimal results in restorative work.

- High Tenacity: Minimize the risk of bur cracking with high tenacity, guaranteeing durability and reliability in prolonged usage.

- Extended Lifespan: Designed for longevity, these burs offer an extended lifespan, contributing to cost-effectiveness for dental laboratories.

- Superior Hardness: Benefit from superior hardness, ensuring consistent and reliable performance in various milling applications.

- Optimal Coating Adhesion: Enhanced coating adhesion ensures the durability of the burs, maintaining the integrity of the cutting edge for precise milling.

- Versatile Compatibility: Suitable for Arum CAD/CAM milling machines and potentially other systems, providing versatility for dental professionals.

Description

Description

Specification

Specification

- Coating: Diamond Coating (DC)

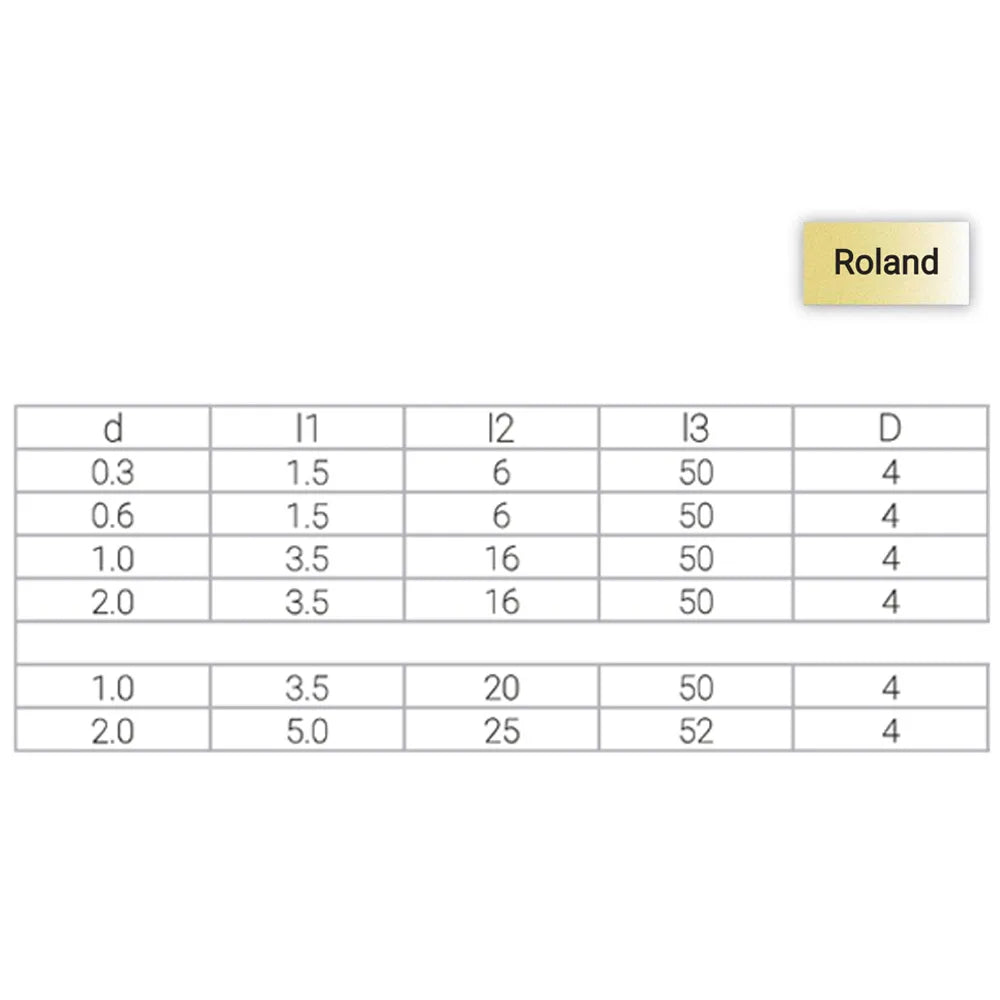

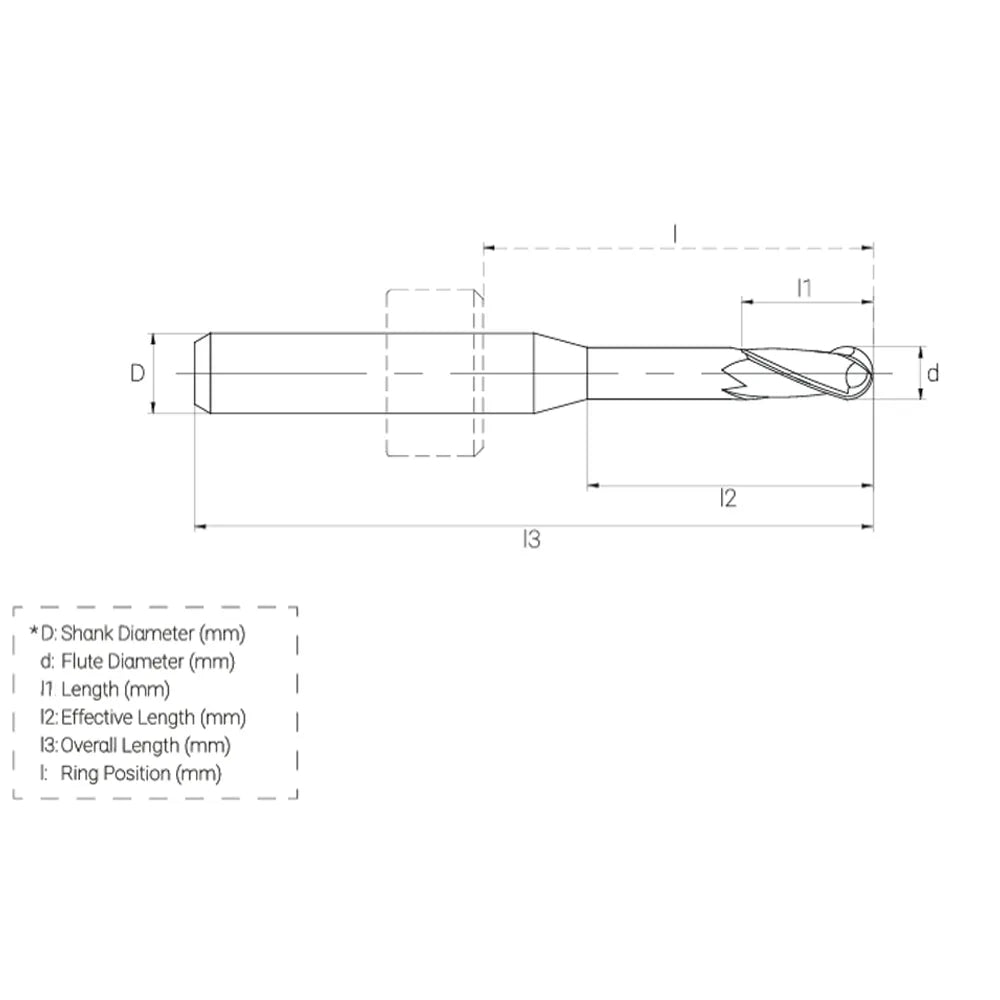

Labodent Milling Burs DC 0.6mm (Roland Type)

- Shank Diameter (D): 4mm

- Flute Diameter (d): 0.6mm

- Flute Length (l1): 1.5mm

- Effective Lenght (l2): 6mm

- Overall Length (l3): 50mm

Labodent Milling Burs DC 1mm (Roland Type)

- Shank Diameter (D): 4mm

- Flute Diameter (d): 1mm

- Flute Length (l1): 3.5mm

- Effective Lenght (l2): 16mm

- Overall Length (l3): 50mm

Labodent Milling Burs DC 2mm (Roland Type)

- Shank Diameter (D): 4mm

- Flute Diameter (d): 2mm

- Flute Length (l1): 3.5mm

- Effective Lenght (l2): 6mm

- Overall Length (l3): 50mm

Packaging

Packaging

- 1 x DC Milling Bur

Direction to use

Direction to use

- Compatibility Check: Confirm the compatibility of Labodent Milling Burs DC with your CAD/CAM milling machine, ensuring a seamless fit.

- Secure Installation: Carefully install the bur into the milling machine.

- Material Selection: Choose the appropriate Labodent Milling Bur based on the dental material you're working with, especially tailored for Zirconia.

- Optimal Settings: Adjust milling machine settings for the specific dental restoration requirements, considering material characteristics and desired precision.

- Steady Application: Engage the milling machine with a steady hand, allowing Labodent Milling Burs DC to exhibit precision and reduce the risk of chipping or cracks.

- Monitoring: Regularly monitor the milling process to ensure the desired shape and precision are achieved. Adjust settings as needed for optimal results.

- Cleaning and Maintenance: After use, clean the milling burs thoroughly. Ensure proper sterilization for a hygienic work environment.

Additional info

Additional info

- Country of Origin: Made in PRC

Warranty

Warranty

- Warranty is not applicable for this product

Product Related Questions

Product Related Questions

Question: How should Labodent Precision milling burs be handled and maintained?

Answer: To maintain optimal performance, Labodent Precision milling burs should be handled with care. Clean them thoroughly after each use to remove any debris or residues. Store them in a clean, dry environment to prevent contamination. Follow manufacturer guidelines for sterilization and maintenance procedures to maximize their lifespan and effectiveness.

Question: Are Labodent Precision milling burs compatible with CAD/CAM milling machines?

Answer: Yes, Labodent Precision milling burs are compatible with CAD/CAM milling machines commonly used in dental laboratories and clinics. They are specifically engineered to meet the demands of digital dental workflows, offering precise and consistent milling results.

Question: How do Labodent Milling Burs DC enhance the dental milling process?

Answer: Labodent Milling Burs DC are precision-engineered CAD/CAM tools, providing a sharp edge and Zirconia compatibility for flawless dental restorations.

Question: What benefits do these burs offer in terms of tenacity and lifespan?

Answer: Labodent's milling burs boast high tenacity, reducing the risk of cracking, and ensuring a prolonged lifespan for cost-effectiveness in dental restorations.

Share