Bio-Art

Bio-Art Vacuum Forming Soft Sheets - Square

Bio-Art Vacuum Forming Soft Sheets - Square

Couldn't load pickup availability

Bio-Art Vacuum Forming Soft Sheets - Square

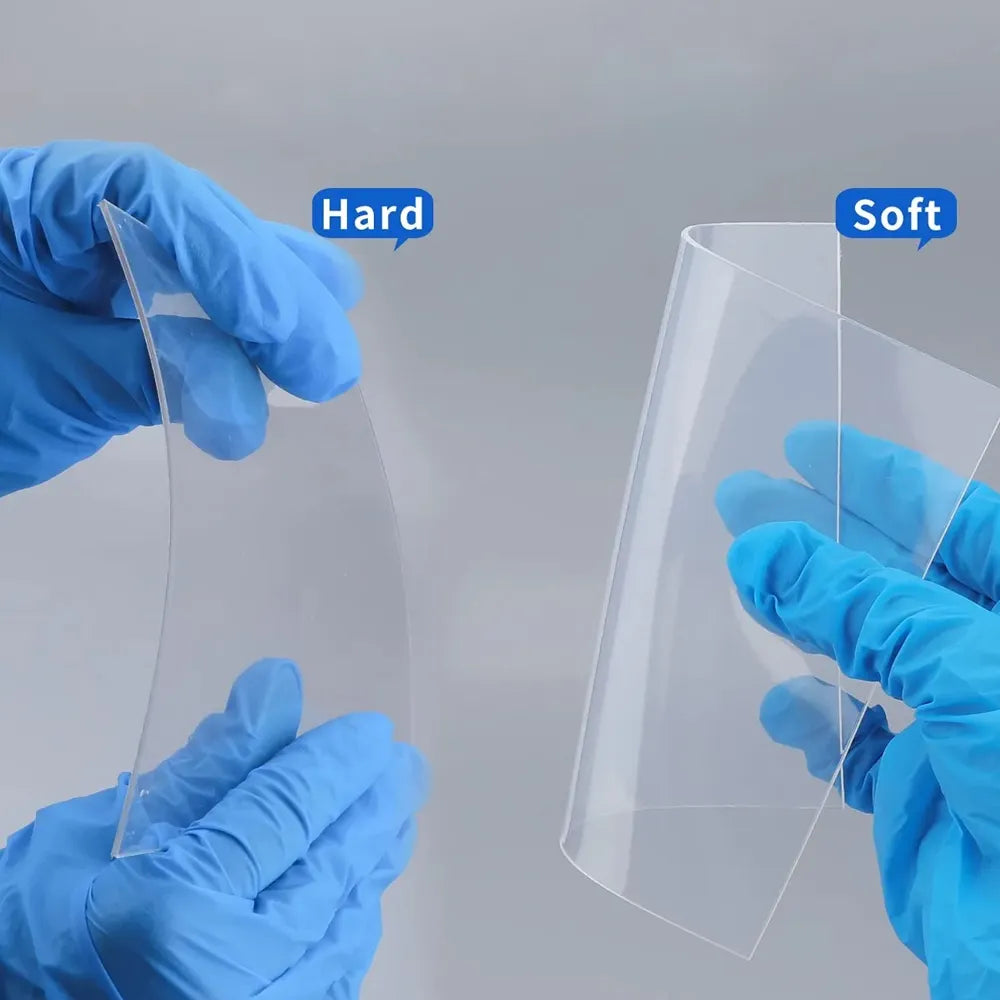

Bio-Art Vacuum Forming Soft Sheets are tailored for dental lab vacuum forming machines, catering to diverse dental applications. Ideal for crafting decolorizing trays, desensitizing trays, orthodontic retainers, sports mouthguards, and night guards, these sheets offer versatility. Available in Soft Sheets with thickness options of 1.0/1.5/2.0/3.0/4.0mm, they provide flexibility to meet various requirements. The thermoformability of these sheets ensures a seamless process with no bubbles, offering toughness and resistance to breakage. In the plasticizing (vacuum forming) process, these sheets are heated in a vacuum-forming machine to achieve optimal plasticization. They are then molded onto plaster models of dental arches, producing high-quality trays for a range of dental procedures.

Applications:

-

Vacuum Forming Soft Sheets (APLP0395)

- Home whitening

- Fluoridation

-

Vacuum Forming Soft Sheets (APLP0667)

- Home whitening

-

Vacuum Forming Soft Sheets (APLP0397)

- Mouthguard Sports

-

Vacuum Forming Soft Sheets (APLP0399)

- Mouthguard Sports

-

Vacuum Forming Soft Sheets (APLP0552)

- Mouthguard Sports

Features

Features

- Versatile Dental Applications: Suitable for crafting a variety of dental appliances, including decolorizing trays, desensitizing trays, orthodontic retainers, sport mouthguards, and night guards.

- Multiple Thickness Options: Available in five thickness options—1.0mm, 1.5mm, 2.0mm, 3.0mm, and 4.0mm—providing flexibility to meet diverse dental needs.

- Compatibility with Vacuum Forming Machines: Designed to be compatible with standard dental lab vacuum forming machines, ensuring ease of integration into existing workflows.

- Optimal Thermoformability: Offers good thermoformability during the plasticizing process, ensuring smooth adaptation to dental models with minimal to no bubbles.

- Uniform Clarity: Provides exceptional clarity in the formed trays, allowing for clear visibility of dental structures and ensuring precision in dental procedures.

- Customization through Trimming: Formed trays can be easily trimmed to fit specific dental requirements, allowing for customization and precision in the final appliance.

- Wide Range of Dental Procedures: Ideal for a range of dental applications, the sheets maximize utility in prosthodontic work, enhancing efficiency in dental laboratories and practices.

- Satisfaction Guarantee: Backed by Bio-Art's commitment to quality, these thermoforming plastic sheets come with a satisfaction guarantee, ensuring reliability and value for dental professionals.

Description

Description

Specification

Specification

- Material: EVA

- Size: 130mm x 130mm

- Color: Translucent

- Hygroscopy (Moisture Absorption): No

- Plasticization Point: Draining of ~1cm

- Thickness: 1mm, 1.5mm, 2mm, 3mm, 4mm

Packaging

Packaging

Vacuum Forming Soft Sheets (APLP0395)

- Pack of 10

Vacuum Forming Soft Sheets (APLP0667)

- Pack of 10

Vacuum Forming Soft Sheets (Pack of 10)

- Pack of 10

Vacuum Forming Soft Sheets (Pack of 5)

- Pack of 5

Vacuum Forming Soft Sheets (APLP0552)

- Pack of 5

Direction to use

Direction to use

- Select Sheet Thickness: Choose the appropriate thickness of Bio-Art Soft Splint Thermoforming Plastic Sheet based on the specific dental application. Options include 1.0mm, 1.5mm, 2.0mm, 3.0mm, and 4.0mm.

- Prepare Plaster Models: Ensure that the plaster models of the dental arches are clean, dry, and prepared for the thermoforming process.

- Preheat the Vacuum Forming Machine: Heat the vacuum forming machine to the recommended temperature suitable for the selected thickness of the plastic sheet.

- Place the Plastic Sheet: Carefully place the chosen Bio-Art Soft Splint Thermoforming Plastic Sheet onto the vacuum forming machine, ensuring it is centered and securely positioned.

- Activate the Vacuum Forming Process: Initiate the vacuum forming process on the machine. The heated plastic sheet will conform to the shape of the plaster models due to the vacuum generated by the device.

- Achieve Ideal Plasticization: Monitor the plasticization process to ensure the plastic sheet reaches the ideal point for molding onto the plaster models. This step is crucial for forming accurate and well-fitted trays.

- Remove Formed Tray(s): Once the vacuum forming process is complete, carefully remove the formed trays from the machine. Exercise caution to avoid any distortions or damage.

- Trim and Finish: Trim excess material from the formed trays as needed and perform any necessary finishing touches to ensure the trays meet the desired specifications.

- Inspect for Quality: Thoroughly inspect the formed trays for quality, checking for uniform thickness, clarity, and proper adaptation to the dental models.

- Repeat as Necessary: Repeat the process as needed for additional trays or different thickness requirements, maximizing the versatility of Bio-Art Soft Splint Thermoforming Plastic Sheets.

Additional info

Additional info

- Country of Origin: Made in Brazil

Warranty

Warranty

- No warranty is applicable for this product.

Product Related Questions

Product Related Questions

Question: Can this be used as an retainer?

Answer: Yes, the Bio-Art Vacuum Forming Soft Sheets - Square can indeed be used to fabricate retainers, among other dental appliances such as night guards and teeth whitening trays.

Question: Can these sheets be used with any vacuum forming machine?

Answer: Yes, Bio-Art Vacuum Forming Soft Sheets are designed to be compatible with standard dental lab vacuum forming machines.

Question: Are these sheets resistant to bubbles during the vacuum forming process?

Answer: Yes, Bio-Art Vacuum Forming Soft Sheets offer good thermoformability with minimal to no bubbles, ensuring a smooth and consistent result.

Question: Is the plastic material tough and resistant to breakage?

Answer: Yes, the plastic material used in these sheets is tough enough to withstand the thermoforming process and is not easily prone to breakage

Share